Hydrocarbons

The recovery of Hydrocarbons from a wide variety of

waste

materials creates the opportunity to establish

Urban Oil Wells.

Huge Environmental Sustainability goals may be achieved with the proliferation of a molecular

Hydrocarbon Recovery

process by massively decreasing the disposal of undesirable wastes such as plastics and

by the capture and conservation of

valuable resources.

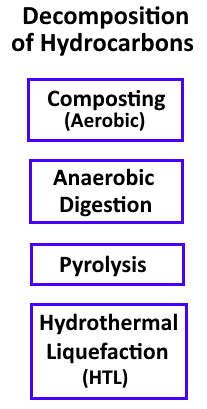

Hydrocarbon Decomposition

An overview of decomposition methods outline some of the strengths and weaknesses of each different approach.

Composting

Composting

works well for

food wastes

but the primary reduction process and subsequent curing stages

require several months to complete.

Anaerobic Digestion (AD)

Anaerobic Digestion can handle food wastes and

organic sludges

well but is less effective with lignans (wood and paper)

and is not effective with plastics, rubber and textiles.

Degradation occurs faster than natural aerobic composting.

Anaerobic

digestion

is a process through which bacteria breaks down organic matter, such as animal

manure,

wastewater biosolids, and food wastes, in the absence of oxygen.

Anaerobic digestion produces two valuable outputs:

biogas

and

digestate

Food waste

mainly consists of carbohydrates, proteins, lipids, and traces of inorganic compounds.

The carbohydrate content of food waste can include

lignin,

hemicellulose, cellulose, starch, and sugars that can be converted into

bioethanol.

Pyrolysis

Pyrolysis

works well with plastics, rubber, textiles, paper and wood,

pre-treatment is required for food and wet wastes to remove excess moisture.

Hydrothermal Liquefaction (HTL)

Various forms of hydrothermal carbonization (HTC) utilize different combinations of heat and pressure to

achieve the rapid reduction or decomposition of carbonous materials.

Hydrothermal Liquefaction

(HTL)

works well on a broad range of hydrocarbon wastes

and the moisture content of the feed stock does not negatively impact the process since

most HTL systems use water as a catalyst.

The HTL process is fast and both HTL and Pyrolysis can be fueled by a percentage of the

product recovered from the feed stock.

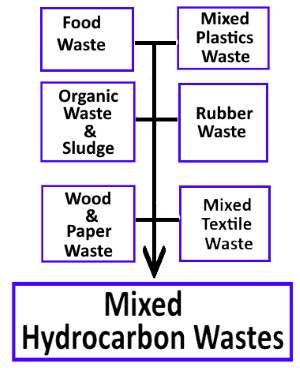

Mixed Hydrocarbon Wastes

The recovery of mixed hydrocarbons is possible by connecting generators

and users of waste materials,

Please feel free to ADD a inquiry to the

Mixed Hydrocarbon Wastes

exchange.

Circular BioEnergy Generator (CBEG)

Any number of events could occur that spark the development of a cottage industry to

own and operate your own Circular BioEnergy Generator (CBEG) or Urban Oil Well by

collecting and converting Hydrocarbon Waste materials into

Bio Crude.

In a decentralized world the establishment of small scale urban oil wells

that may be located close to the source of waste feed stock give cause to rethink potential energy independence.

Chemical Recycling

The current terminology of

Chemical

Recycling or

Molecular

Recycling of plastics

refers to the thermal decomposition of hydrocarbons into a partially reduced, condensed intermediary stage

mixed hydrocarbon raw product known as

Bio Crude

or Bio Oil.

Please take this opportunity to explore

Bio Refining.

Hydrocarbon Splitting

The Recovery 2.0 system embraces the concept of

Hydrocarbon Splitting

in a process where Hydrocarbon gases are

converted into

clean Hydrogen

and

solid carbon.

Depolymerization

In the plastics recycling industry Depolymerization typically refers to the partial decomposition of plastics or polymers

into specific monomers.

It is a common goal to rebuild these refined monomers into complex polymer chain for specific market designations.

This is not the same process as full

Molecular

decomposition.

Depolymerization primarily requires very clean feedstocks and typically can not tolerate contamination,

so this process is not applicable for mixed wastes.

Re-Refining

The refining of hydrocarbons is a well established industry and

the supply of Bio Crude or synthetic crude oils generated from waste recovery projects

is a compatible raw feed stock.

Many newly adopted participants of the Chemical Recycling process seem to share the opinion to

reinvent the wheel by Re-Refining, distilling, cracking and segregating the intermediate oil fractions,

and some feel the need to produce finished petrochemical products to achieve a new form of

energy independence.

Re-Refining is a common method for the recovery of

Used Motor Oil

and other petrochemicals and waste oils.

Hydrocarbon Recovery Information

For anyone seeking current information or research data on Hydrocarbon Recovery,

you may access and ask your

Recycling Questions

to a core group of experienced and knowledgeable recycling industry professionals.

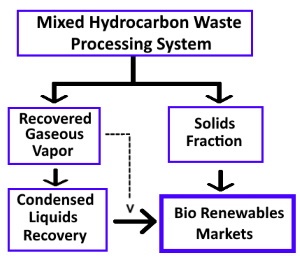

Renewable Natural Gas (RNG)

The decomposition of organic or hydrocarbon based materials liberates a gaseous fraction known as

BioGas.

This type of material is derived from a number of sources including landfill gas, recovered digester gases

and pyrolysis off gasses.

The collection and cleaning of

Renewable Natural Gas (RNG)

or methane CH4 can directly replace Natural Gas and may be sold at a premium price into green markets.

Renewable Natural Gas (RNG) may also be further refined into clean

Hydrogen.

Bio Crude

The Hydrocarbon recovery process captures a liquid fraction of mixed light and heavy bio oils referred to as

Bio Crude.

This material may be sold as is into the open market or be further upgraded by

Re-Refining.

Bio Solids

The solid fraction of materials captured from the Hydrocarbon Recovery process is largely a carbon material,

packaged and sold into the

carbon markets.

As with recovering any waste stream it is important to implement a comprehensive

Residual Materials Management

strategy to deal with the metallic and inorganic inert materials contained in the original raw feed stocks.

Other Hydrocarbon Wastes

Wastes from fossil fuel byproducts,

oil,

gas, coal and petrochemical wastes,

aromatic hydrocarbons,

residues, sludges and pollutants

have spread throughout our air, water and earth.

We have been living in a throwaway society and that strategy must change, we need to adopt a

responsible approach to the stewardship of managing our environment.

Efforts are required for immediate

Hydrocarbon Recovery

and regeneration to obtain environmental equilibrium.

Hydrocarbon Recovery

The complete reduction of signal elementals with the selective recovery of

Carbon

and

Hydrogen

from mixed Hydrocarbon

wastes

can be viewed as an ultimate method of recycling.

The

regenerated

materials are segregate into pure Hydrogen & Carbon commodities

and are directly marketable worldwide.

Hydrocarbon Cycle

The

Recovery 2.0

system attempts to take advantage of a Hydrocarbon Cycle.

The Thermal Reduction of

mixed wastes

that contain largely hydrocarbon based materials are reduced and

split

into Hydrogen and Carbon.

Using a reaction that recombines hydrogen and carbon in the absence of oxygen, the primary energy required to drive the

thermal reduction

process is generated.

As well as heat, this reaction produces a byproduct of

hydrocarbons

which are captured directly into the recovery stream

and the cycle continues.

One of the

Waste.net

objectives is to advance the adoption of waste reduction efforts.